Computer Numerical Control or CNC is a cutting-edge technology tool in which machinery movements are controlled by computer systems. As such, CNC machines are able to operate efficiently and in a way that saves time and reduces cost, in addition to enabling the production of identical, interchangeable parts.

Now, let’s take a look at the origin and development of CNC machines.

Table of Contents

Origins of CNC Machines

In 1751, a ‘metal frame turning machine’ was created, with the goal to devise machinery that would provide higher precision of mechanical operations than what would be possible by using any hand-made method. It was the first of many, and it represented the start of industrialization.

However, the true concept of CNC is deeply connected with the principal notion of Numerical Control (NC).

Early Stages of Numerical Control Machines

The automation of machinery brought on the concept of Numerical Control, with manufacturing machines being made with tools that were present at that time. These tools were then customized with motors that enabled the movement and control of the machinery.

The initial NC machines were introduced in the 1940s, followed by moderately more developed versions in the 1950s. With the implementation of analog and digital computer technology into this system, Computer Numerical Control was developed.

The First Computer Numerical Control Machine

In the mid-1940s, Jim Parsons searched for ways to enhance and improve the productivity rate of helicopter blades. Working with IBM, Parsons studied and developed a system that manufactured templates for the blades. Since the system fabricated parts by reading and using preprogrammed information that was entered into it by punch cards, this is recognized as the first numerical controlled machine to date. This was also the beginning of the CNC machining technique.

Further Development of CNC Machines

By the end of the 1940s, Massachusetts Institute of Technology (MIT) started conducting numerous Air Force research projects. After the early stages of planning and researching, they designed a prototype of a milling machine. A team of researchers, led by Professor J.F. Reintjes participated in this project.

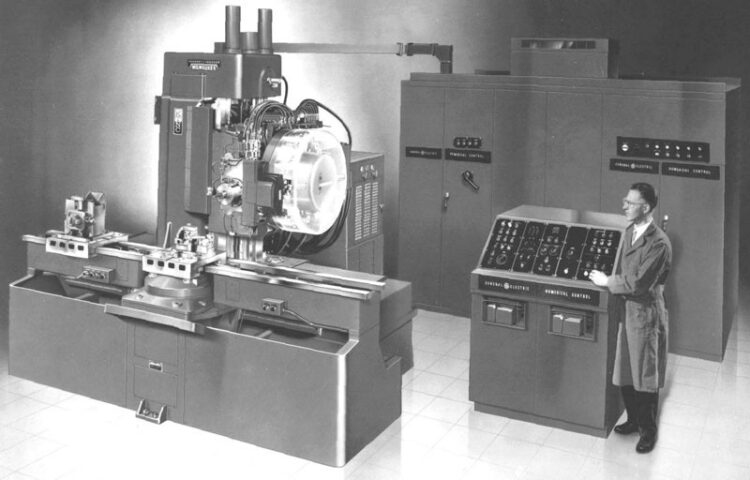

Cooperating with MIT, Richard Kegg made the Cincinnati Milacron Hydrotel – the initial CNC milling machine in 1952. He patented it under the name ‘Motor Controlled Apparatus for Positioning Machine Tool’ in 1958. According to ArtMachinig.com, this was the starting point of the commercial development of the technology.

As the development of digital technology accelerated, especially in the 1960s and 1970s, so did the production process automation. Following the trend, CNC machines started taking the shape of the ones we have now. It is not rare to find Computer Numerical Control machines in the majority of industries today, especially with the use and advancement of computer technology. Moreover, it is fairly easy for people to make or buy their own personal CNC machines.

The Main Components of CNC Technology

Even though there are major differences between the early CNC machinery and the ones we have today, all automatically controlled machines still consist of three crucial parts – the drive and motion system, the feedback system, and the command function.

As technology continues to progress and as it becomes more and more advanced, it will be interesting to witness what will be added to the long and ever-growing history of CNC technology. Visit SummitMT to read more about CNC machining.